When the summer heat intensifies, so does your office: in case you have a cooling tower system in place to cool down your office premises, it is key to keep them well maintained and serviced. Properly maintaining and servicing your cooling towers will help sustain the ideal lower condenser water temperatures, which results in an optimized energy efficiency, lower utility bills and avoiding downtime.

Whether you are managing the premises yourself or having an expert manage it for you, implementing a maintenance plan that includes planning for seasonal weather extremes means you will actually be protecting the cooling system from very costly summertime fatigue.

Underneath these lines you will find a few key steps to include in your summer cooling towers maintenance program:

Disinfect and clean cooling towers

According to official regulations, all cooling towers must be properly disinfected and cleaned at least twice per year. This actually means removing scale deposits that may have built upon the fill. Limescale build-ups can decrease the efficacy and performance of your system and will eventually lead to premature deterioration of the unit. Disinfecting your unit on a regular basis prevents algae as well as biofouling growth. When left unattended, algae growth may potentially lead to legionella growth. Legionella bacteria cause Legionnaire’s disease, which is dangerous and at times fatal illness.

Water treatment

A cooling tower water treatment program is a series of measures and technologies that remove potentially damaging impurities from the tower’s feed water, circulation water or blowdown. Cooling tower maintenance and servicing is more than simply ensuring the components are in a good working order, you need to also pay attention to the water quality. There are many cooling water treatment programs including deposit and scale control, corrosion inhibitors, chlorine dioxide, biocides and legionella control. It is highly advisable to run a legionella risk assessment regularly with the help of a qualified professional. By regularly checking your maintenance program you will increase the cooling tower productivity, and this will help you reach the pre-established sustainability goals by reducing water and energy usage while making the office premises safe for your employees and clients.

Regular inspections and servicing of cooling towers

- Pumps: inspect your water pump to guarantee it’s operating correctly. This means to actually check if it’s on and off when it needs to be. The pumps need to run when the chiller does. Usually, chiller systems rely on a water pump to carry hotter water to the chiller for cooling. In order to service the pumps ensure your pump is lubricated, as well as periodically check the alignment.

- Fans: a poor quality airflow can reduce the transfer of heat from the water to the air. Airflow interruptions may occur due to loose components, incorrect fan alignment or because of a lack of gearbox maintenance. Whether the cooling tower has direct-drive or belt-drive fans, both require regular maintenance to guarantee reliable performance.

Calibrated sensors and accurate functioning

- Temperature: temperature sensors are obviously an essential component of the mechanical systems. When it comes to the functionality of a cooling system in an office, these sensors are vital.

- Flow: usually cooling tower systems monitor the flow to and from the cooling tower. These determine how much of the actual capacity is in use. If they aren’t properly calibrated, they will lead you to think you have more system capacity or less.

- Water level: making sure that your water level controller is correctly functioning is truly crucial to the operation. Validating that it is controlling adequately and that the alarm is really working as it needs to in the case of a low water condition will actually save your operation if there is a mechanical failure.

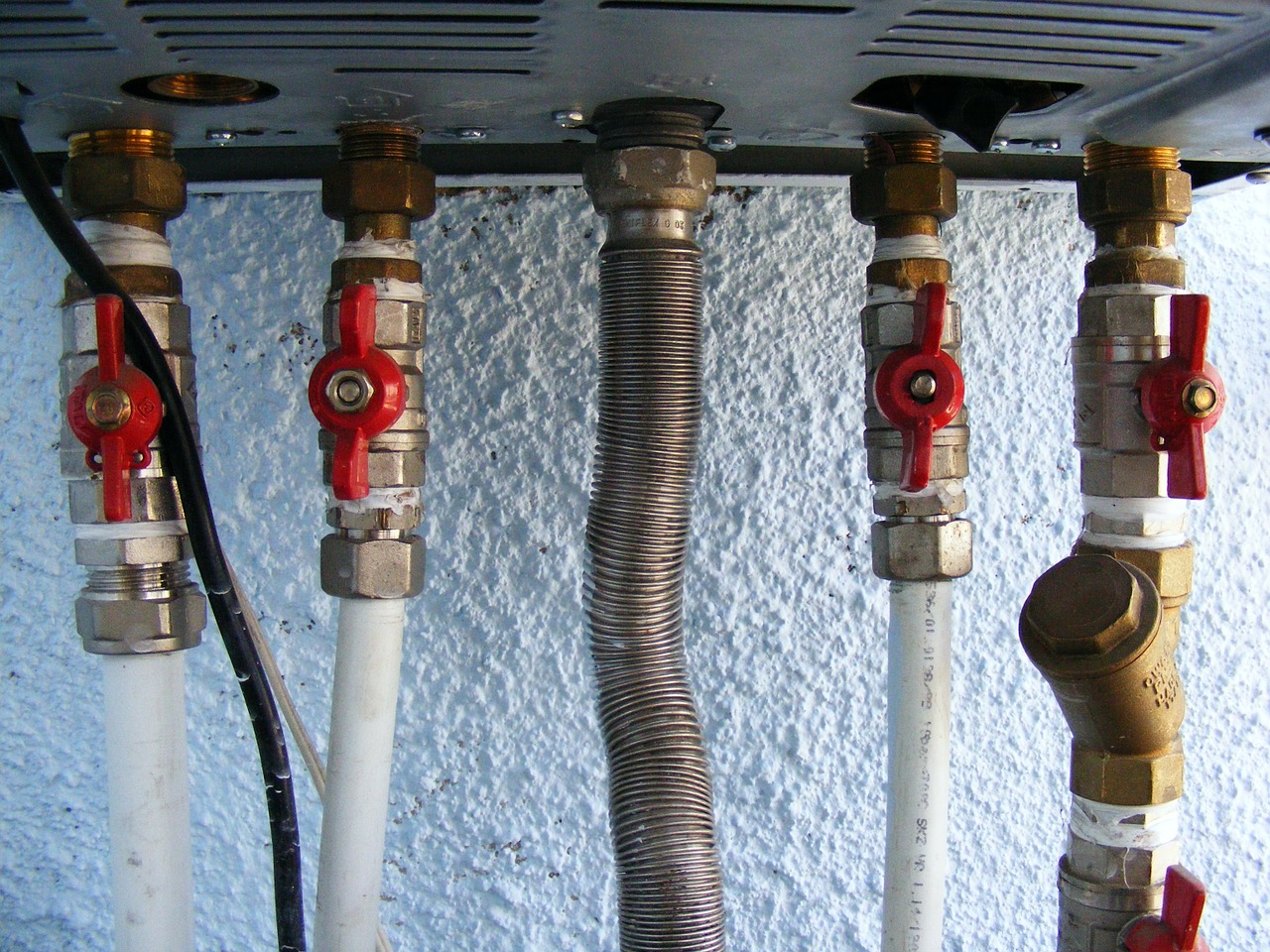

Fully working automated valves

- Modulating: these modulating valves are frequently overlooked. It’s not uncommon to find out they are out of calibration. If the valve does not close or open completely it can have a negative impact on your system and even leave you with less efficiency as well as capacity.